Seamlessly integrated into SAP ERP or SAP S/4HANA

How value-adding a machine or system works is a central piece of information for manufacturing companies. Information about this is provided by the Overall Equipment Effectiveness (OEE) indicator or the OEE calculation. This Overall Equipment Effectiveness was developed in the 1980s at the Japan Institute for Plant Maintenance (JIPM). Today, the value occupies a prominent position among the KPIs. The reason: The OEE calculation brings together all the factors that determine the performance of machines and systems – or even production lines: availability, performance and quality. The Overall Equipment Effectiveness thus makes it comprehensible as to how well equipment exploits the existing potential and where losses occur.

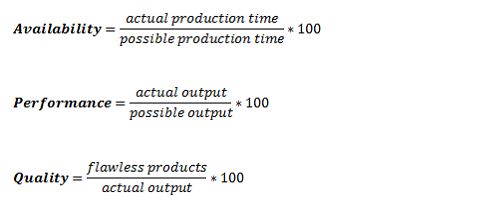

For the OEE calculation, different data from the shop floor must be related to each other:

Through these divisions, the three individual factors take percentages. The higher these values, the better. In any case, it tends to be because the OEE indicator results from the multiplication of all three factors. After all, it would be of little use to a company if availability and performance are enormously good, but only scrap is produced.

In order for manufacturing companies to benefit from the calculation of overall equipment effectiveness, they should use the key figure correctly:

top MES provides the Overall Equipment Effectiveness for your machines and systems and – as something extremely important for success – offers a wide range of possibilities for analysis and visualisation.

As part of top MES, the OEE analysis – such as the Production Data Collection or the Machine Data Collection – can be seamlessly integrated into SAP ERP or SAP S/4HANA. That means: The calculated key figures are based on the corresponding SAP documents. So there is only one reliable data truth. Regardless of the OEE, many other key figures can become relevant in manufacturing companies. In order to use them sensibly, a solution for the Business Intelligence can be integrated directly in the MES.